How Industrial Area Scan Cameras Can Save You Time and Money in Production Lines

Do you wish there was a faster and more efficient way to ensure the quality of your products? Look no further than industrial area scan cameras. These powerful tools have revolutionized the manufacturing industry, offering real-time monitoring and inspection that can save businesses both time and money. In this blog post, we’ll explore industrial area scan cameras.

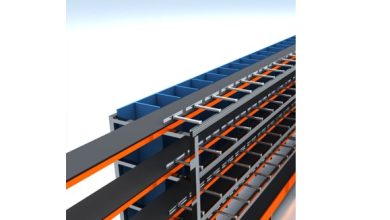

Introduction to Industrial Area Scan Cameras

Area scan cameras are an essential part of any modern production line. They provide a quick and easy way to check for defects or contaminants in products without the need for manual inspection. This can save a lot of time and money in the long run, as it reduces the chance of faulty products being sent out to customers.

There are many different types of area scan cameras on the market, so it is important to choose one that is suitable for your particular application. For example, some cameras are designed specifically for inspection tasks, while others may be better suited to general-purpose imaging.

When choosing an area scan camera, there are a few key considerations to keep in mind. Firstly, you need to decide what resolution you require, which will determine the maximum size of the defect that can be detected. Secondly, you need to consider the field of view, indicating the size of the area that can be imaged by the camera. Finally, you need to think about the frame rate – this is how many images per second the camera can capture.

Benefits of Using an Industrial Area Scan Camera

An industrial area scan camera can save you time and money in production lines by providing a high-speed, accurate way to inspect products. These cameras can be used to detect defects in products, identify assembly problems, and track product movement. By using an industrial area scan camera in your production line, you can avoid costly mistakes and improve your bottom line.

How to Maximize Efficiency and Safety When Installing a Camera

When it comes to installing a camera in an industrial environment, there are a few things you can do to maximize efficiency and safety. Here are a few tips:

- Make sure the camera is properly grounded. This will help prevent static electricity from damaging the camera.

- Use proper mounting hardware. This will ensure that the camera is securely attached to the equipment or surface it is being installed on.

- Follow the manufacturer’s instructions. This will help you avoid any potential problems during installation and ensure that the camera is installed correctly.

Conclusion

Industrial area scan cameras are a great way to save time and money on production lines. With the ability to detect defects quickly and accurately, these cameras can help reduce waste, increase efficiency, and improve product quality. By implementing industrial area scan cameras into your production line, you will be able to maximize productivity while minimizing costs. So if you’re looking for ways to maximize your profits without sacrificing quality or wasting resources, consider purchasing an industrial area scan camera today! If you are looking for a quality one, you should not miss SmartMoreInside, which is a reputable brand famous for its high-quality products and satisfactory service.